Эта страница доступна также на Русский языке

Эта страница доступна также на Русский языке

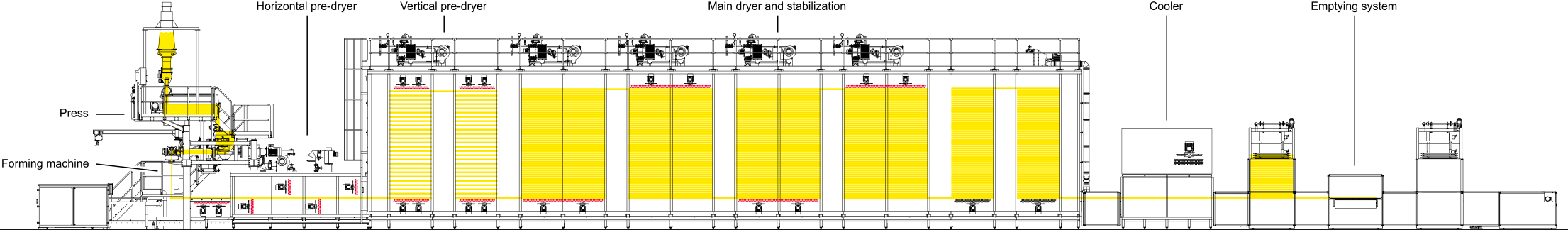

The most important features of this equipment are TURBOMIX technology and low-speed of extrusion, which is achieved thanks to the high-efficiency compression screws: these characteristics allow to obtain a very homogenous dough. The press can be fitted either with Total Vacuum System or with traditional technology.

Through the forming machine, the laminated pasta sheets or otherwise the extruded pasta take the desired shape (nest, matasse, lasagna, etc.) for the subsequent spreading on trays.

Thanks to a powerful ventilation, the surface of the Special Shaped Pasta is heated to maintain the desired shape, prevent sticking and to prepare the product for the subsequent vertical predrying phase.

This phase of approximately 50 minutes, performs a quick heating of pasta and the preparation for the next drying phase.

Thanks to a rising/descending trays movement inside the main dryer and to a sophisticated thermohygroregulation system, different for each phase, it is possible to obtain a perfect drying and stabilization of any kind of Special Pasta Shape.

Provided with a heat exchanger entirely manufactured in stainless steel installed in a dedicated external unit, the cooler allows to cool Special Shaped Pasta and to prepare the pasta for the next packaging phase.

There are different models of emptying devices: it is possible to flip the tray to obtain a bulk packing or there is the possibility to have an unloading unit with pieces counting and tidy feeding of the packaging system.

ARS (AXOR Remote Service) is the automation and supervision system completely developed by AXOR.

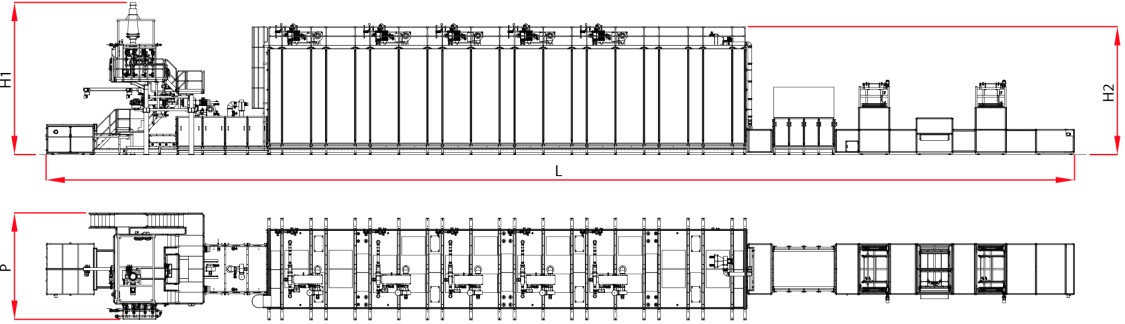

| Output capacity (Kg/h) | Press | Tray dimensions | H1 (mm) | H2 (mm) | L (mm) | P (mm) |

|---|---|---|---|---|---|---|

| 500 | 1.130.L 1000 | 1000x1500 | 7700 | 6800 | 49400 | 4410 |

| 800 | 2.130.L 2000 | 2000x1500 | 7700 | 6800 | 49400 | 5410 |

| 1000 | 2.130.L 2000 | 2000x1500 | 7700 | 6800 | 49400 | 5410 |

| 1200 | 2.145.L 2000 | 2000x1500 | 7700 | 6800 | 54000 | 5410 |