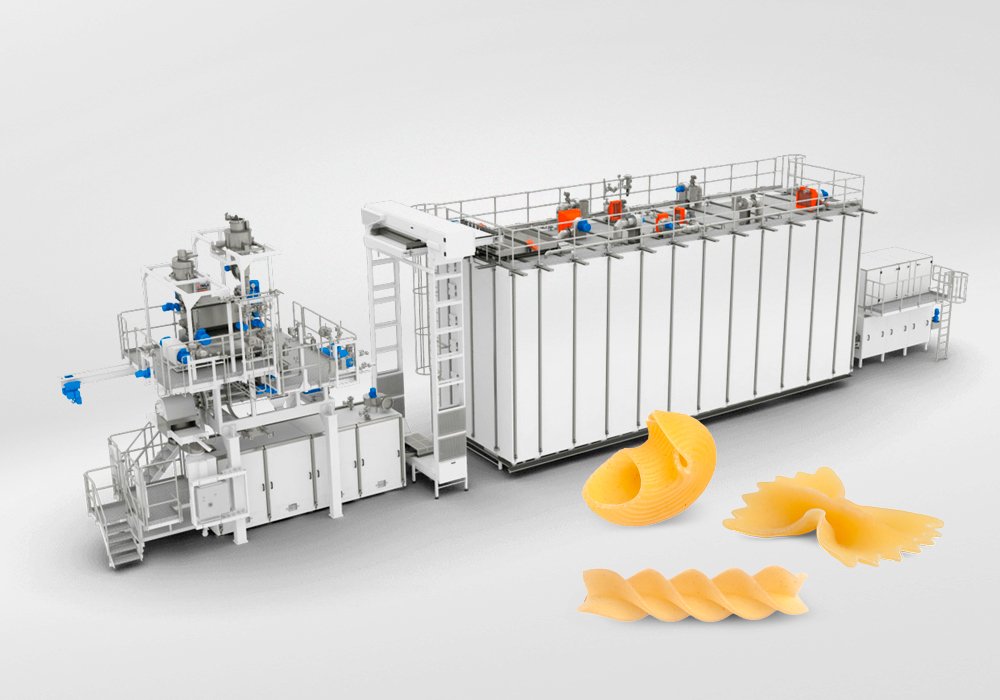

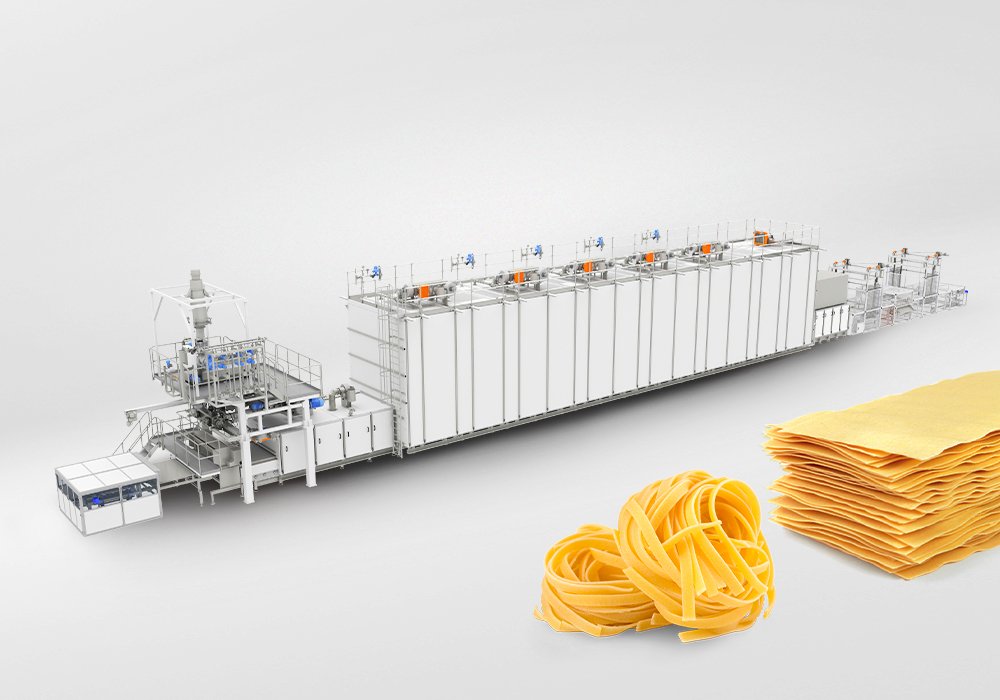

Press

The most important features of this equipment are TURBOMIX technology and low-speed of extrusion, which is achieved thanks to the high-efficiency compression screws: these characteristics allow to obtain a very homogenous dough. The press can be fitted either with Total Vacuum System or with traditional technology.

Press Assembly

Mixing Tanks with Vacuum Airlock

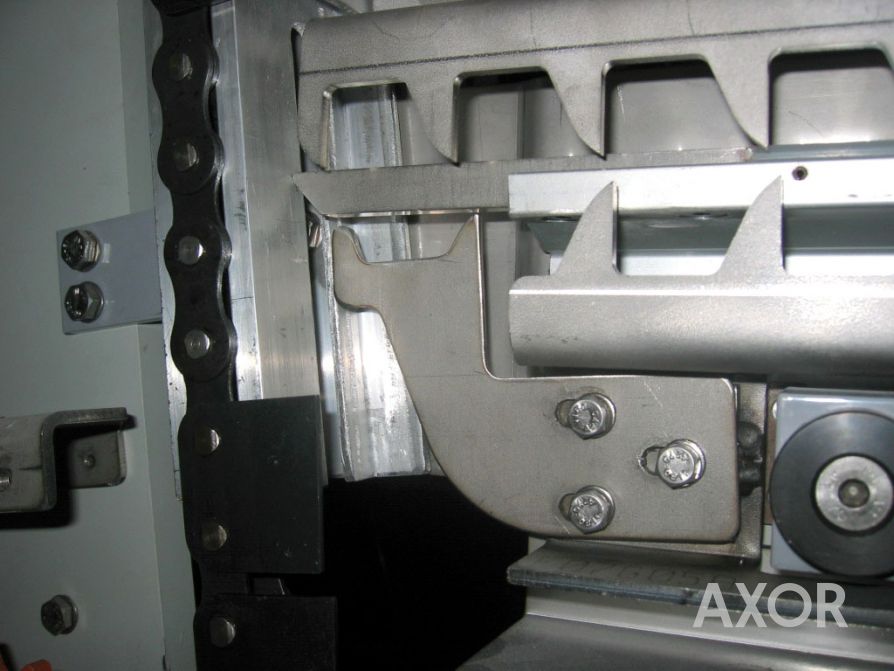

Spreader

This equipment allows a homogeneous spreading of the Long-Cut Pasta on 2550 mm sticks. It is provided with an automatic system for fresh scraps recovery and a pneumatic conveying system to the press.

Spreader

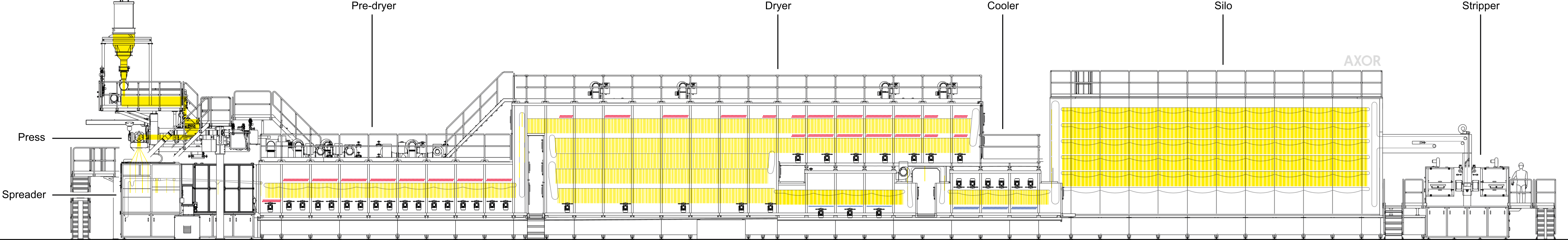

Pre-Dryer, Dryer and Cooler

The surface of the Long-Cut Pasta is pre-dried, with a continuous hot air flow, to prepare the product for the subsequent drying phase.

A permanent and homogeneous drying of Long-Cut Pasta is permitted by the switching from ventilation phases to rest phases, which are totally controlled by automatic thermohygroregulation systems and are combined with a mechanical double rack guide.

Provided with a heat exchanger entirely manufactured in stainless steel, the cooler allows to cool Long-Cut Pasta and to prepare the pasta for the next storing and packaging phase.

Pre-Dryer

Dryer

Cooler

Storage Silo and Stripper

During the night shift of production, it is possible to collect the Long-Cut Pasta on sticks. Every tier has an independent motorization to synchronise the loading and unloading of the storage silo, through an automation system devoted to this equipment.

The stripper automatically removes the sticks and cuts the pasta to the length required for the next phase of packaging.

Storage Silo

Long-Cut Stripper

Storage silo and two Strippers at the end of the production line

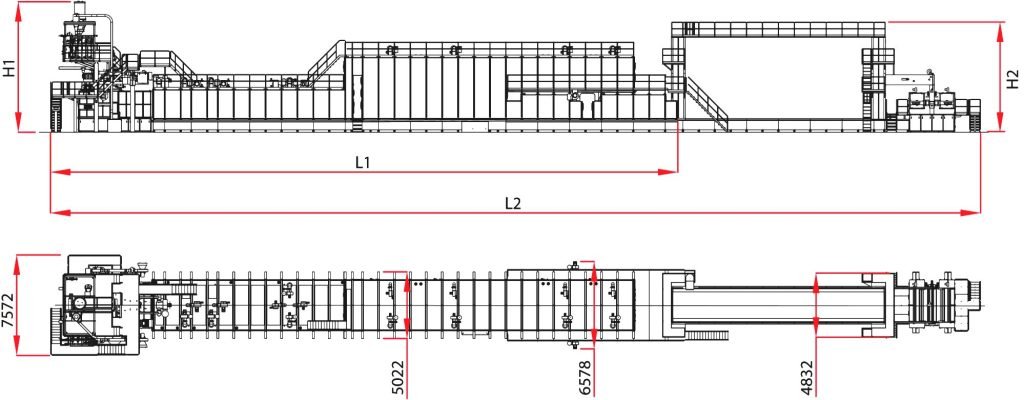

Capacity and dimensions

| Output capacity (Kg/h) | Press | Spreader | Line composition | H1 (mm) | H2 (mm) | L1 (mm) | L2 (mm) |

|---|---|---|---|---|---|---|---|

| 2000 | 1.245.L 2550 | ST.AX-2 | LPL-TI 3 + Silo | 9300 | 7500 | 39200 | 58000 |

| 3000 | 2.210.L 2550 | ST.AX-3 | LPL-TI 5 + Silo | 9500 | 7500 | 42200 | 69000 |

| 3500 | 2.210.L 2550 | ST.AX-4 | LPL-TI 5 + Silo | 9500 | 8300 | 47300 | 76000 |

| 4000 | 2.245.L 2550 | ST.AX-4 | LPL-TI 5 + Silo | 10000 | 8300 | 50900 | 81000 |