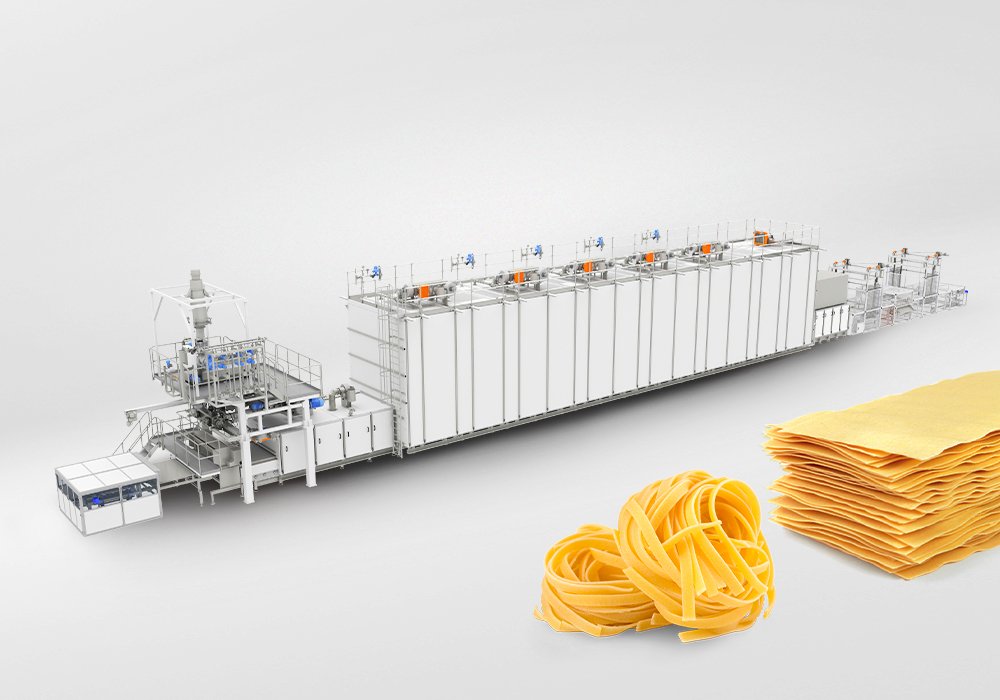

Press

Pasta production process starts here: in the vacuum mixing tank, raw materials and water are dosed to obtain the dough. Then, thanks to the mechanical action of the high efficiency compression screws, the dough reaches the perfect compactness that is necessary for pasta to keep its shape at the exit of the die head.

The press can be fitted either with Total Vacuum System or with traditional technology.

The cutting unit is a completely independent unit, fixed at the press legs. It is suitable for cutting any pasta shape and also to fit the “penne” cutter device

Mixing Tanks with Vacuum Airlock

Shaker and Bucket Elevator

Pasta drying process starts here. The shaker is fitted with a new motion device (patented), which allows a significant energy saving. In the shaker, the surface of the pasta is dried very quickly by hot air, to prevent sticking in the next steps of the pasta production process.

Shaker

Bucket Elevator

E.N.A. Dryer

The complete pasta drying process occurs in two zones of the E.N.A. dryer: pre-dryer and main dryer, each one having its separated thermohygroregulation control unit. A pre-drying phase of approximately 40 minutes, followed by a drying phase of approximately 2 hours, to end with a stabilization phase of approximately 30 minutes, allows a high-quality production using any kind of raw materials. E.N.A. dryer is fitted with high density fiberglass panels, internally lined with stainless steel sheets and silicone rubber gaskets.

ENA Dryer

The Bucket Elevator feeds the Spreader at the top of the Dryer

Cooler

The air/water cooler is fitted with an external cooling unit to lower the pasta temperature and to make it suitable for storage and/or packaging.

Short-Cut Cooler

Short-Cut Cooler

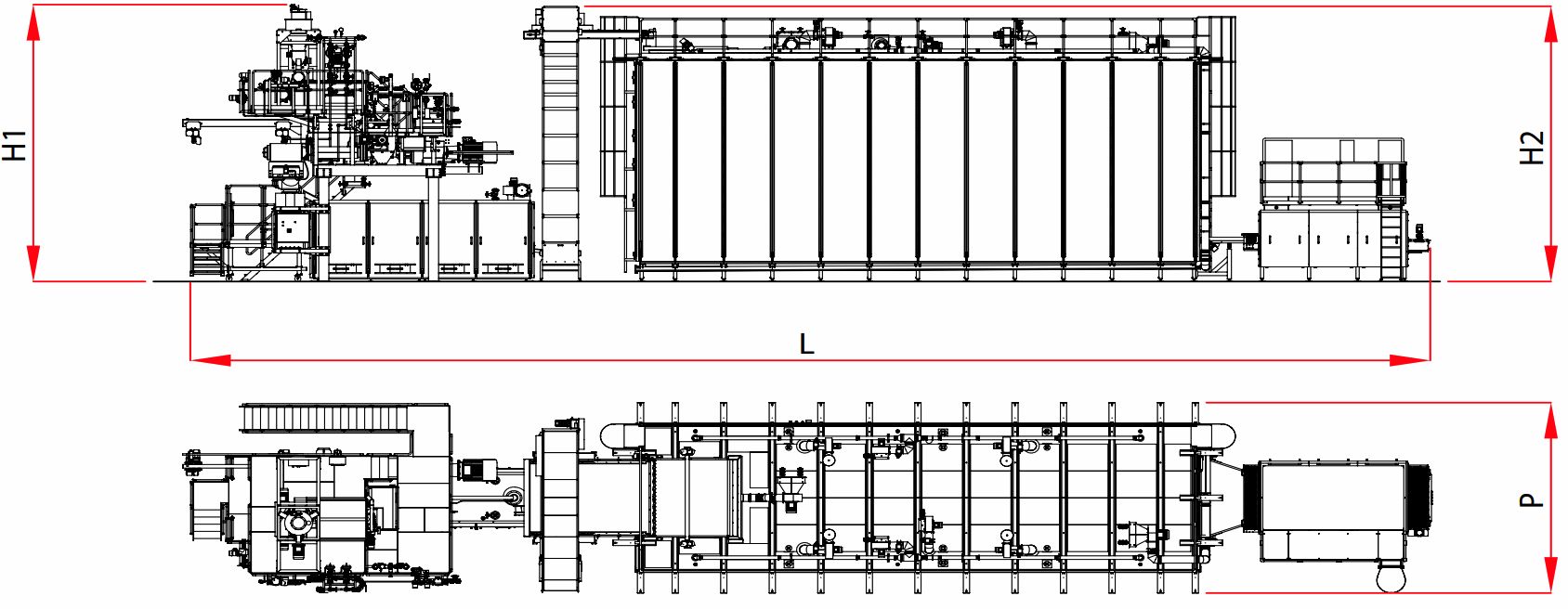

Capacity and dimensions

| Output capacity (Kg/h) | Press | Line composition | H1 (mm) | H2 (mm) | L (mm) | P (mm) |

|---|---|---|---|---|---|---|

| 700 | 1.145.C 400 | TMVS 700 - E.N.A. DD 9/9 | 6300 | 6200 | 23100 | 4860 |

| 1000 | 1.165.C 460 | TMVS 1000 - E.N.A. DD 11/9 | 6300 | 6200 | 25500 | 4860 |

| 1500 | 1.210.C 520 | TMVS 1500 - E.N.A. DD 11/11 | 7000 | 6900 | 27000 | 4860 |

| 2000 | 1.210.C 600 | TMVS 2000 - E.N.A. DDL 13/11 | 7000 | 7700 | 29600 | 5310 |

| 2500 | 1.245.C 635 | TMVS 2500 - E.N.A. DDL 13/13 | 7500 | 8600 | 31500 | 5310 |

| 3000 | 1.245.C 670 | TMVS 3000 - E.N.A. DDL 13/13 | 7500 | 8600 | 31500 | 5310 |

| 4000 | 2.210.C 600 | TMVD 4000 - E.N.A. DDL 18/13 | 9600 | 8600 | 38600 | 5310 |

| 5000 | 2.245.C 635 | TMVD 5000 - E.N.A. DDL 22/13 | 9800 | 8600 | 41000 | 5310 |

| 6000 | 2.245.C 670 | TMVD 6000 - E.N.A. DDL 22/15 | 9800 | 9400 | 41000 | 5310 |