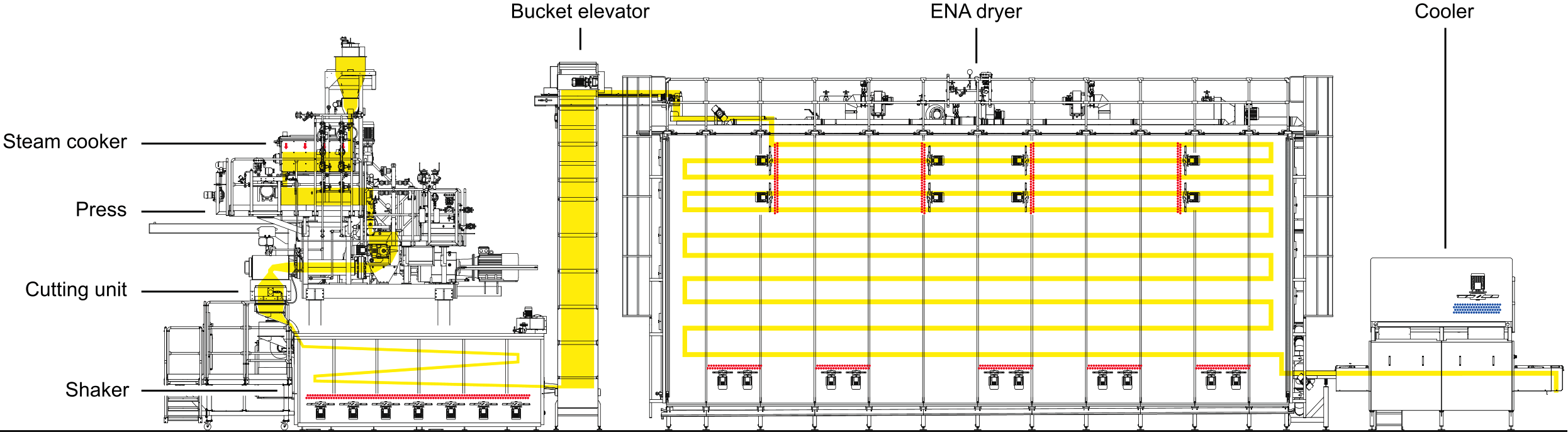

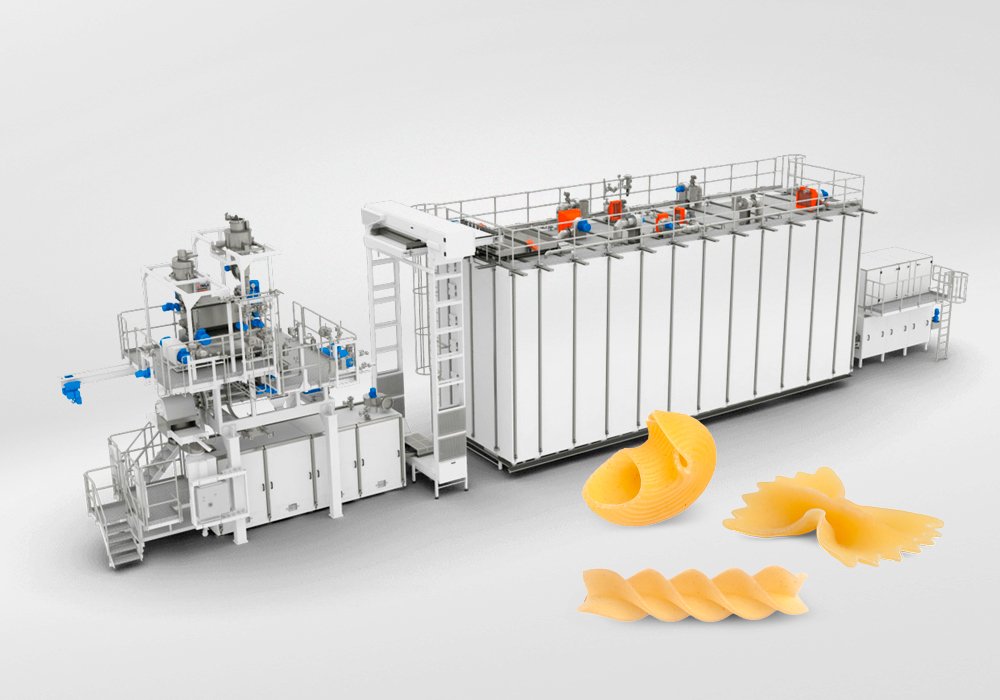

Raw material steam cooker

It is possible to produce pasta with any kind of gluten-free raw material (corn, rice, quinoa, etc.). During this phase, thanks to a precise volumetric dosing and to a powerful system of steam injection, the starch contained in the raw material is gelatinized, to be ready for the next forming phase.

Press

The raw material, already gelatinized and humidified in the previous phase, is formed in a vacuum tank and then extruded with high efficiency compression screws, necessary to keep the pasta shape, at the exit of the die head.

The cutting unit is a completely independent unit, fixed at the press legs. It is suitable for cutting any pasta shape and also to fit the “penne” cutter device.

Shaker

The shaker is fitted with a new motion device (patented), which allows a significant energy saving. In the shaker, the surface of the pasta is dried very quickly by hot air, to prevent sticking in next steps of the pasta production process.

E.N.A. Dryer

The complete pasta drying process occurs in two zones of the E.N.A. dryer: pre-dryer and main dryer, each one having its separated thermohygroregulation control unit. A pre-drying phase of approximately 40 minutes, followed by a drying phase of approximately 2 hours, to end with a stabilization phase of approximately 30 minutes, allows a high-quality production using any kind of raw materials. The E.N.A. dryer is fitted with high density fiberglass panels, internally lined with stainless steel sheets and silicone rubber gaskets.

Cooler

The air/water cooler is fitted with an external cooling unit to lower the pasta temperature and to make it suitable for storage and/or packaging.

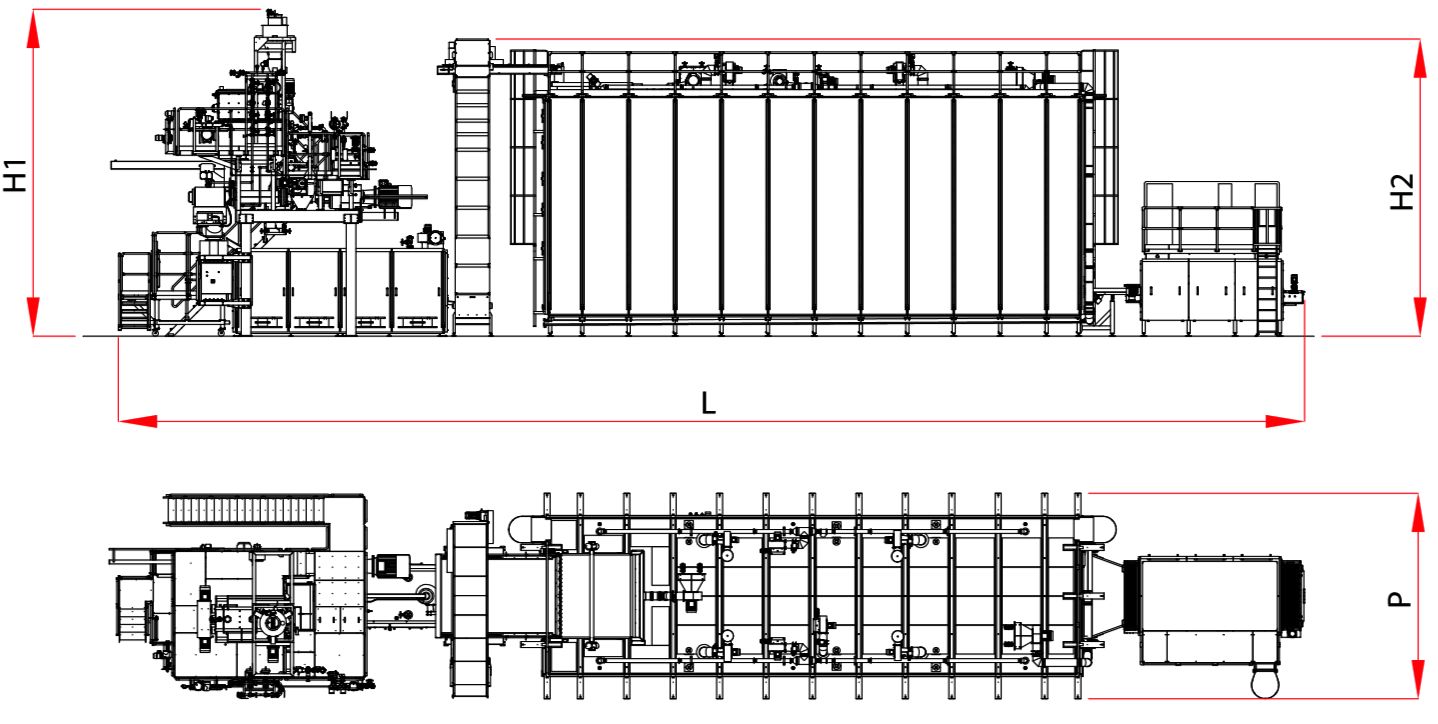

Capacity and dimensions

| Output capacity (Kg/h) | Press | Line composition | H1 (mm) | H2 (mm) | L (mm) | P (mm) |

|---|---|---|---|---|---|---|

| 700 | 1.145.C 400 | TMVS 700 - E.N.A. DD 9/9 | 8000 | 6200 | 23100 | 4860 |

| 1000 | 1.165.C 460 | TMVS 1000 - E.N.A. DD 11/9 | 8000 | 6200 | 25500 | 4860 |

| 1500 | 1.210.C 520 | TMVS 1500 - E.N.A. DD 11/11 | 8500 | 6900 | 27000 | 4860 |